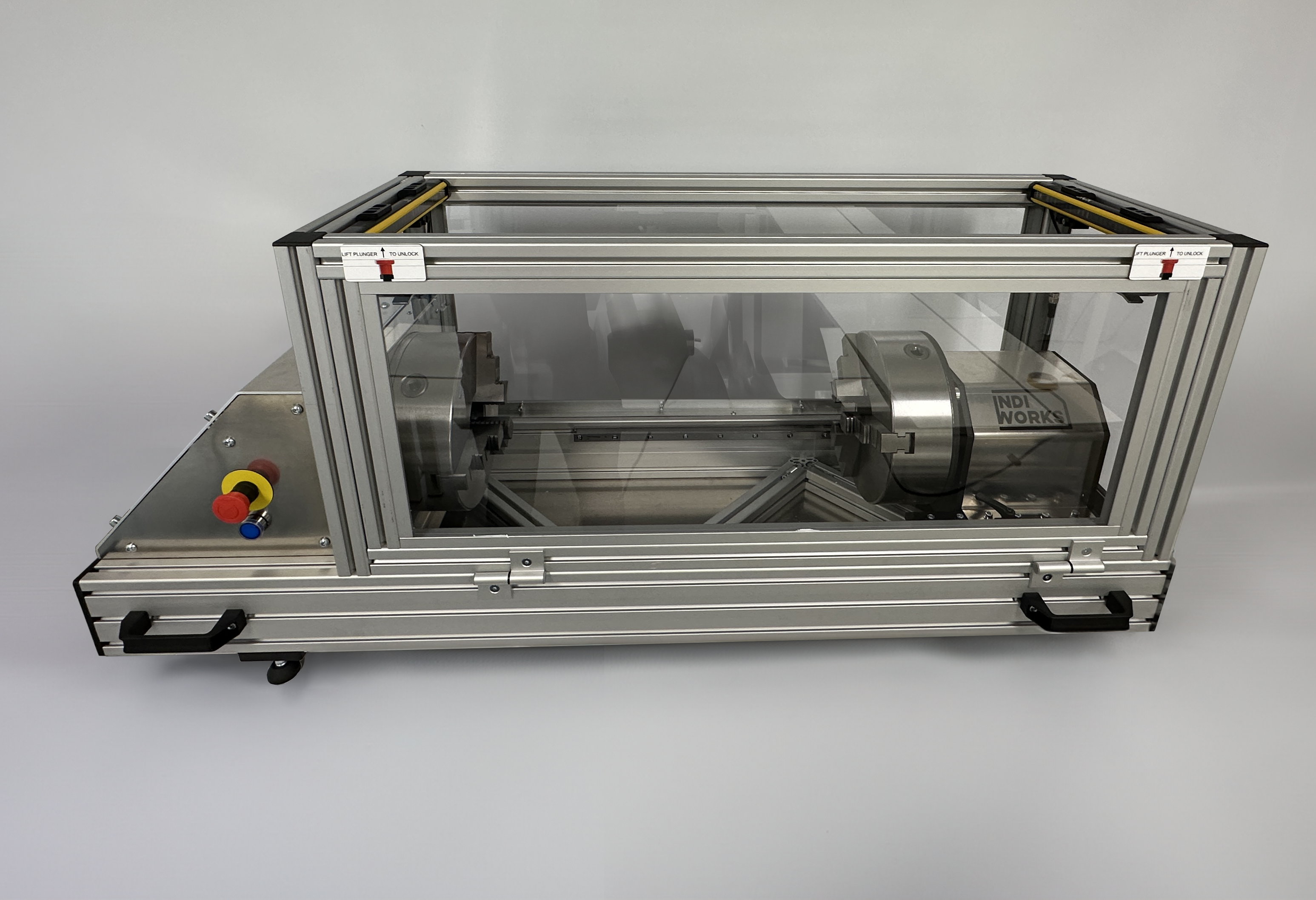

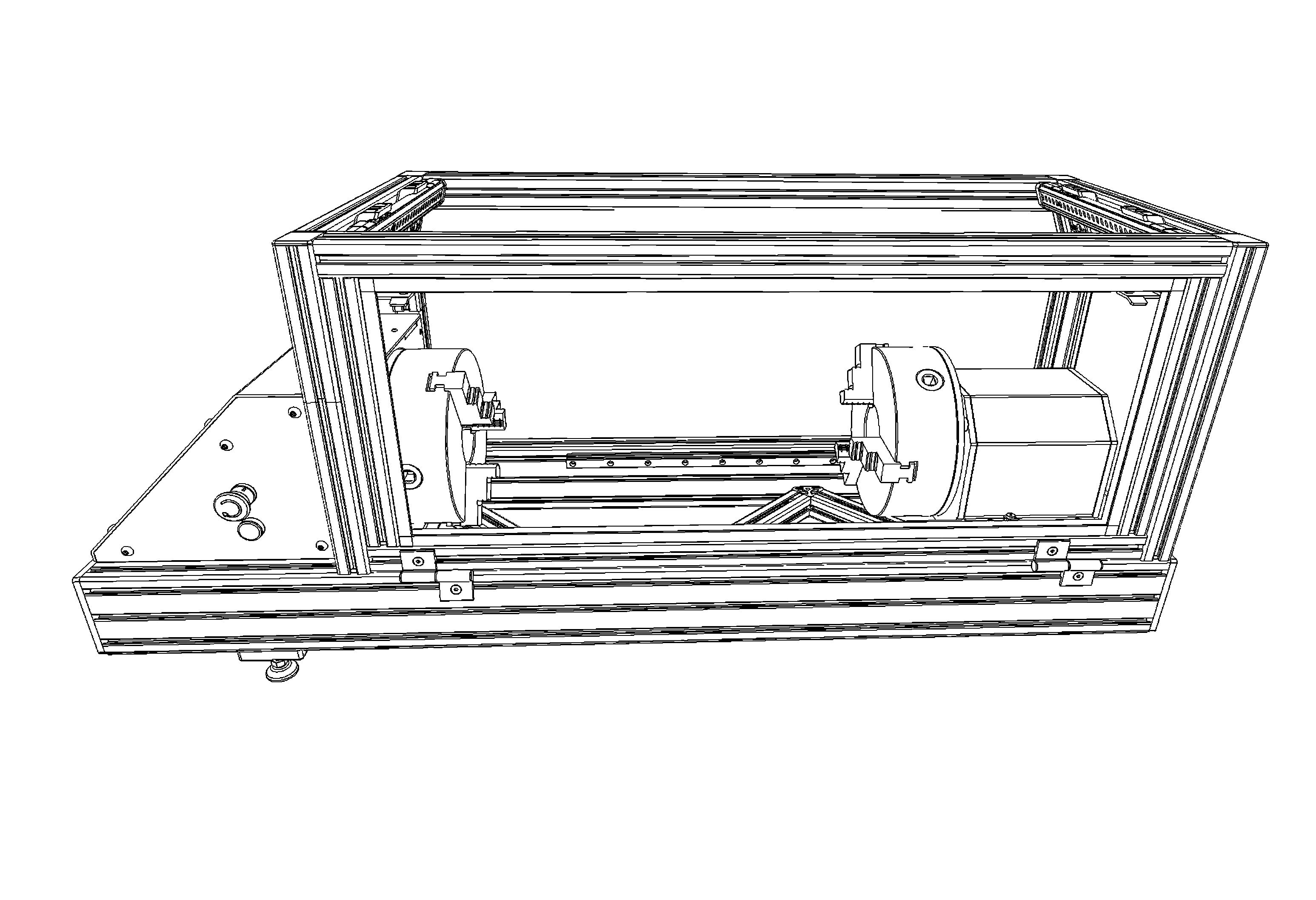

Rotary indexer

Performing quality inspections in a repeatable and efficient way is a key capability for safeguarding quality across many production processes. Machine-vision methods allow highly reliable automated checks to be integrated into production.

Developing machine-vision algorithms is a crucial step for reliable defect-detection systems. To support an optimal and time-efficient development process, manufactured parts must be presented to camera systems in a repeatable manner.

The Rotary Indexer was developed as a test platform for developers, integrating all functional requirements while also ensuring machine safety and product flexibility.

This machine enables the client to:

- Clamp both small and large, light and heavy components reliably.

- Rotate components so they can be positioned repeatably, at the required accuracy and speed.

- Work with the machine safely and confidently.

At INDIworks, we continue to push boundaries in customer-specific solution development. Together with the client, we define requirements in detail and then deliver the best possible solution within practical limits such as timeframe and budget.

Curious what INDIworks could do for your company? Get in touch today!