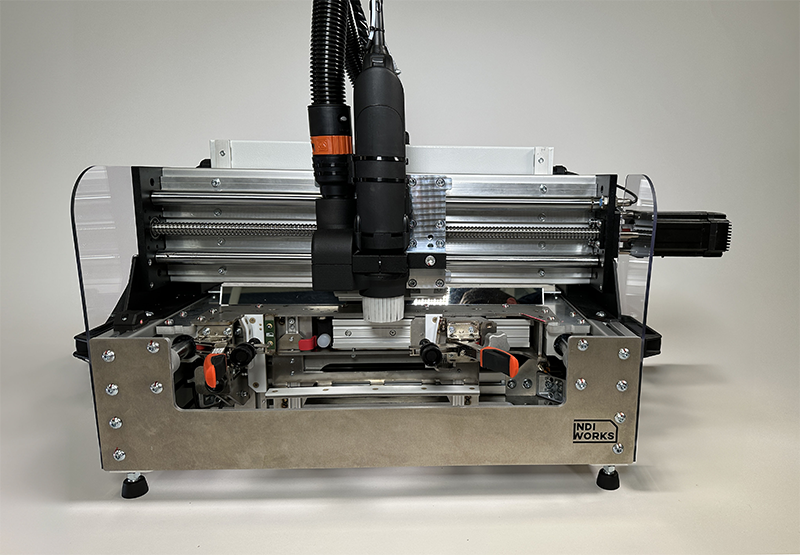

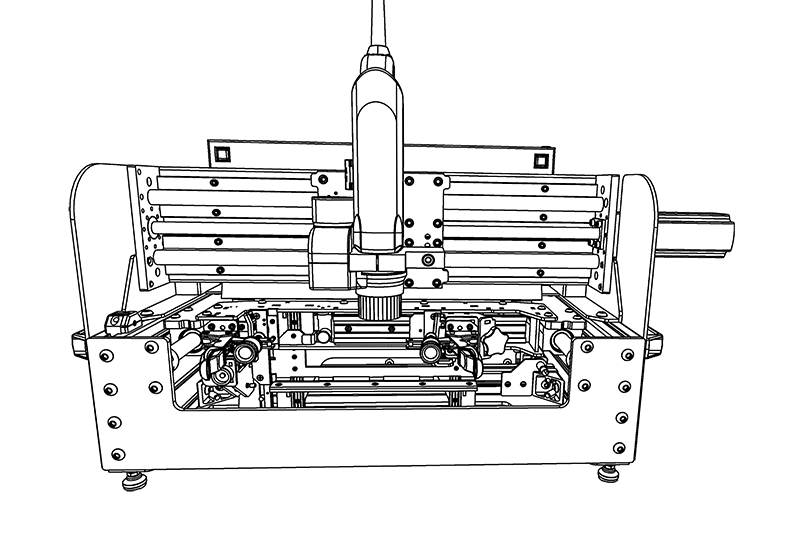

Battery cell cutting machine

In today's increasingly electrified automotive industry, battery quality is critical. Batteries need to perform flawlessly to unlock full vehicle performance. If issues arise, a thorough analysis is required. For this battery project, the client needed a controlled method to open prismatic battery cells.

The challenge was clear: develop a repeatable day-to-day solution for cutting open prismatic battery cells with the required precision and control, without damaging internal structures or materials.

The final solution consisted of several key elements:

- A unique mechanical clamping system to position and secure the battery cell optimally, suitable for multiple cell formats.

- A cutting procedure tailored to the client's required opening method, ensuring internal structures remain intact while maintaining full control throughout the operation.

- A compact machine design that allows installation inside a system with an inert atmosphere.

- A user interface and control options that allow operators to run both manual and automatic cutting procedures in a very intuitive way.

- A cell detection and measurement system to guarantee safety and flexibility across multiple cell formats.

Our team delivered an innovative, compact machine that opens prismatic battery cells consistently and reliably. The solution combines our expertise in mechatronics, precision engineering and industrial sensing technologies in one integrated machine.

At INDIworks, we keep pushing boundaries. Whether the challenge is battery analysis or another complex technical question, we are ready to turn your requirements into breakthrough solutions.

Want to know how INDIworks can help you tackle technological challenges and optimise your processes? Get in touch today!